General

I purchased my Alwest in the Summer of 2002 with one dead engine and the intent to re-power her. I did a substantial amount of internet research into the power systems available at the time and concluded that I should work with Volvo-Penta. I won’t bother you with the details that led up to that conclusion, but suffice to say it was detailed. One of the major factors was that my boat was originally powered by Volvo-Penta, and one of their sales-engineers had some experience with the boats. However, I was getting mixed messages from all contenders as to the appropriate power to install. The gist of the messages was that the Alwest was a “Semi-displacement” hull and that there was no point in installing too much power. I had some trouble with that message as I had some experience aboard my parents’ Alwest 37 and I knew that the twin V-8’s could get the boat moving pretty quickly. At about this time, there was a fantastic Article in Passagemaker (Text) that explained the difference in hull types. I decided that the boat design should not be classed as “Semi-displacement” and engaged the services of a consultant to help me understand what was going on. I spent a very entertaining afternoon with Stephen Leake learning about the dynamics of water and hull shapes. He had a piece of software to model hull performance. Much of the information below is either from the software or a key input into the software.

A number of scenarios were run using a hull modeling software package (HydroComp NavCad). The two major variables were the “model” and the overall vessel weight. The software had provision to use a large number of theoretical models and accurate selection may have resulted in a higher degree of confidence in the calculations. However, there was insufficient data available on the hull shape to select anything other than general purpose models. The two models selected were the general purpose Semi-displacement and Planing models. A number of vessel weight data points were run through each model to permit comparison of the effect of weight on performance. Because the software was generally meant for small ship modeling, there were a number of compromises that will have resulted in unpredictable errors. Given that this exercise was mostly for educational purposes, these errors were considered acceptable. It was interesting to note that the Semi-displacement and Planing models were run with precisely the same input parameters and yet yielded substantially differing results.

Data Provided

| Parameter | Value |

| Water type | Standard Fresh |

| Mass density | 1.934 slug/ft3 |

| Kinematic viscosity | 1.226e-5 ft2/s |

| LWL | 33 ft |

| Proj chine length | 30 ft |

| Max chine beam | 9 ft |

| Displacement | 8.7 Long tonne |

| Proj bottom area | 250 ft2 |

| Deadrise midchine | 10 deg |

| Longitudinal CofG forward of transom | 18 ft |

| VCG above BL | 2 ft |

| Shaft angle | 0 deg |

| VCE above BL | 0 ft |

| LCE fwd transom | 0 ft |

Performance calculations

Performance was calculated as the amount of horsepower required to drive the vessel at fixed increments over a range of speed (8 to 40 knots at 4 knot intervals). The results are as follows

|

Speed |

HP required Planing |

HP required Semi-displacement |

|

8 |

40 |

37 |

|

12 |

83 |

162 |

|

16 |

141 |

466 |

|

20 |

215 |

1,072 |

|

24 |

307 |

2,122 |

|

28 |

417 |

3,794 |

|

32 |

548 |

6,300 |

|

36 |

699 |

9,862 |

|

40 |

872 |

14,720 |

The graph below shows these values as a plot.

Discussion

Although the Alwest behaves more as a planing hull than semi-displacement, disproportionately high horsepower is required to achieve higher speeds when compared with similar sized Deep-V craft. It is my assumption that this is due to the relatively shallow Modified-V hull, resulting in 2 related effects:

1) Low angle of attack resulting in low dynamic lift as speed increases

2) Deeper chines resulting in longer distance to lift the boat to dry the chines

These two effects work together to limit the practical top speed of the boat. Until the boat is running on the bottom only (chines dry), the water-plane area will remain relatively constant. This is true at any practical speed for the Alwest. Given that the drag from skin-friction increases geometrically with speed, correspondingly large increases in power are required for every speed increment. In contrast, the chines on a Deep-V are close to the water surface, requiring only minimal lift distance to have the boat run on the bottom of the hull. This, combined with the high angle of attack, creates high dynamic lift, drying the chines even sooner, resulting in a steadily decreasing water-plane area for the Deep-V as speed and lift increase. This results in a more linear relationship between required horsepower and speed once the boat is planing. There may be some speed where the Modified-V hull lifts high enough out of the water to permit reducing water-plane area. But this speed is beyond the 40 knot range of the calculations performed and would require horsepower in excess of the calculated 872 HP already required to achieve 40 knots.

Fitting the Model

There are a small number of known anecdotal data points to compare with the theoretical model

| Speed | Horsepower | Source |

| 25 MPH (22 Knots) | 340 | Alwest brochure |

| 30 MPH (25 Knots) | 450 | For sale ad. for re-powered Alwest |

| 25 MPH (22 Knots) | 500* | Quadrium |

*It is my belief that the Quadrium gearing/propeller selection is optimized for economy at low speed cruise. This results in an inability to pull full rated RPM and HP at WOT.

The Power-Speed curve generated by the theoretical model for a Planing hull was adjusted to align closely with the known anecdotal data points by shifting the horsepower column against the speed column. Given the shape of the curve, it will tend to result in large errors at the low speed portion and higher accuracy at the high speed portion of the curve. Given that an engine can not operate continuously at maximum output, selection of an engine should be based on the horsepower available for cruising. For our purposes, we will assume a gas engine can operate at 75% of full output.

|

Speed |

HP required |

Gas engine total HP for cruise (Assume 75% available) |

Logical gas engine selection (x 2) |

|

8 |

83 |

111 |

|

|

12 |

141 |

188 |

|

|

16 |

215 |

287 |

|

|

20 |

307 |

409 |

4.3l V-6, 225 HP |

|

24 |

417 |

556 |

5.7l V-8, 260 HP |

|

28 |

548 |

731 |

7.4l V-8, 385 HP |

|

32 |

699 |

932 |

|

|

36 |

872 |

||

|

40 |

? |

This table will have highest accuracy at the known data points. All other data points are extrapolated and should not be trusted for anything other than discussion purposes.

Conclusion

The Alwest is a planing hulled boat. Its Modified-V design is efficient for low-speed planing. Higher speeds require disproportionately high horsepower with correspondingly high capital costs and fuel consumption.

Thanks to:

Stephen Leake

Postscript

All of the above information was generated prior to performing the re-power of the boat. We finally selected the Volvo-Penta 4.3GXi with SX leg combination. I won’t say it was the perfect choice, but it certainly exceeded our performance expectations. The boat cruises nicely at 25MPH at around 3,300 RPM and has a top speed of 39MPH at around 4,500 RPM.

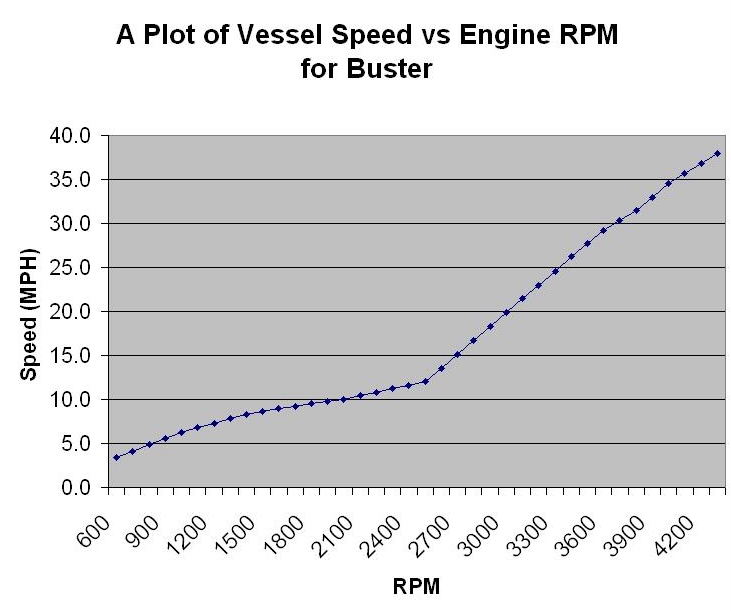

The graph below was generated from data collected during speed trials with Buster. The conditions were ideal, with a very slight chop, no wind and no current. The vessel was moderately loaded (1/2 tanks gas and water) and was clean of plant growth on the hull and legs. For this exercise we left the legs in the full-down position. We used our GPS to measure the speed and ran engine speeds from idle to Wide-Open at a number of different engine speeds as measured by the engine tachometers. There will be slight errors from the instrumentation used.