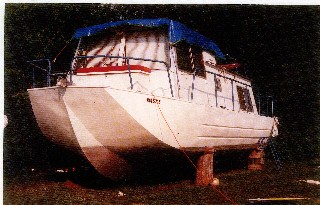

Brand: Alcan

Model Year: 1968

Model: 290

Hull Number: HUE16CW4303

Registration Province: Ontario

Registration: 86E5248

Home Port: Toronto Island Marina

Engines: OMC 350

History

Our Alcan 290 was purchased on a whim in 1998, …something about the name of Alcan got us to look, and so we assumed the product must be good. The previous owners of one year, sadly spent the year repairing and rebuilding drive and motor, and then decided that boating was not for them. The boat was named “Holdfast” when we found her , and rumor has it that a scottish fellow around the south end of Georgian Bay owned her for many years, and his resultant patchwork repair is what we inherited. Holdfast, may have inspired the scottish side of its past owner, but our children had better ideas. And so one day it was noted, particularly when she was out of the water, that our Alcan 290 looked curiously like a beached little blue whale. And so her unofficial new name is: Little Blue Whale

Hull

The hull of the 290 has a stiffened and welded front structure with solid transom support typical of the larger boats. The difference with construction is within the main length of hull under the cabin areas, which have been foam filled with a closed cell foam. This was injected at construction between the wooden interior structure, floor, and the aluminun outer hull. This foamed package provides rigidity and insulation. As well if you want safety, rumor has it these boats will float if they take on water. Best not to try.

After our third season, i took it upon myself to prepare the hull for painting. Never again. The boat had never been painted below the water line, and was starting to show some minor pitting. Surprisingly the aluminum oxide protected the bottom very well over the 30 years. I disc sanded and cleaned the hull below and above water line, and after priming the bare metal below the water line applied 3 coats of epoxy. Above the water line we primed and painted over the many layers of paint once smoothed, and just last year we applied the missing light blue stripe. We have used the interlux system throughout and it has held well. Our only mishap was that our anti- fouling started to peel after the first season. To my dismay I discovered that I had waited too many days allowing the epoxy to cure, before applying the anti-fouling. According to Interlux, we are now obliged to sand off any remaining anti-fouling product before re-applying with the latest anti-fouling products. Since our boat sits in very clean water, anti-fouling is hardly necessary, and it was suggested to wait a number of years and let the remaining amount wear off as much as possible before re-visiting the hull with sand paper and roller. Good advice.

Motor:

The boat has a OMC 350 block with 225 HP. Since re-building she has about 150 hours.

After two seasons learning how to maneuver in canals and locks with the motor constantly quitting on us, we decided it was time for a new 4 barrel Holly carburator, since no one was capable of re- building the re-built one which was on the motor. We did eventually find a new (not re-built) Holly 4-barrel, and since then we can trust the motor to run slowly and smoothly for docking.

Interior:

We have installed a new holding tank with all new fittings and pipes and new head. We had a new stainless steel fresh water tank made and installed with a hand pump at the galley. We got rid of all shoddy electric water pumps, tossed out old leaky taps, and decided to keep things simple. We are campers and canoeists from early years, and we figured we already had it too good with a roof and motor. We threw out the old electric RV fridge under the counter and filled the space with a custom built drawer unit. The existing oversized drawer unit at the base of the stairs which had a counter top, was converted into a super insulated ice box, with top access. An additional drawer unit was made to fit the closet, since the space was poorly conceived. All along all the cabinets have been faced with teak, in keeping with the original feel of the boat.

Exterior:

The original upper wood structure is made of solid wood structural framing with plywood exterior, faced and glued with an aluminum skin and associated aluminum edge detail extrusions.

This year we have begun repair to the upper roof. This job is in progress, and we hope to have the damaged roof members stronger than before, with new crezon ply replacing the damaged sections, lagged quarter sawn fir for ceiling supports, and a white TPO membrane roof cover over the entire upper roof.

Our intent is to restore the boat as close to original as possible. In so doing we are maintaining the original hardware and detailing where ever possible, as well as the 60’s flavor of teak and paneled interior.